The power industry is witnessing rapid changes thanks to technology. Networks are evolving, and the Industrial Internet of Things (IIoT) has taken root, with autonomous systems contributing to the rise of decentralized generation.

Heraclitus, a Greek philosopher, has been credited for saying, "Change is the only constant in life." For those in the power generation business, it seems nothing could be truer–especially concerning how electricity is generated and delivered today.

From deregulation in the 1990s to today's changing and evolving generation portfolios, our industry has had to adapt, and everyone knows more change is on the horizon.

The good news? As Isaac Newton is credited with saying, "If I have seen further it is by standing upon the shoulders of giants," or in other words, learning from those that discovered earlier. While the electric utility industry is experiencing continued disruption, the good news is that there are giants from which we can learn.

Securing a Better View of the Market

Enter the Industrial Internet of Things (IIoT). In March 2014 a group of forward-thinking companies got together to form the Industrial Internet Consortium (IIC). The charter was to "bring together the organizations and technologies necessary to accelerate the growth of the Industrial Internet by identifying, assembling and promoting best practices." In short, the participants recognized the evolving landscape across industries and the need for unbiased guidelines and standards for the evolution of industrial/autonomous systems. Today, the IIC is a leading resource for all industries going through an "Industrial Internet" type evolution.

The power generation industry in recent years has witnessed a rapid acceleration of technology. Processors have continued to get faster, smaller, and cheaper. Networks are evolving and increasing in availability. Applications that need both of these have absolutely benefited. One thing is certain in these modern systems: things are happening fast.

Autonomous systems are showing up everywhere, from sharing the roads we drive on, to drones that inspect our infrastructure. However, there is a big difference between these fast, autonomous systems and the systems used in electric grid control–they do not work within seconds or minutes, they make decisions and take actions in fractions of seconds. They do not communicate large files of data to a server and then wait for instruction. They act. They optimize. They communicate with each other. Things happen fast.

When things happen fast, requirements change. The same is true in the power industry. As we see fossil fuel-based generation become less economical and retired, renewable energy takes hold. The issue is that one large spinning coal-fired plant is not easily replaced with tens of thousands of smaller/residential distributed energy sources. With the centralized plants, we have had great predictability, great performance, and great understanding of the dynamics. With the influx of distributed energy resources (DERs), these things change. A lot.

From Centralized to Distributed

As our world becomes more and more connected, and as a myriad of new connected devices appear, traditional "hub-and-spoke" systems start to fall apart. In all server-based control and optimization systems there is latency; it takes time to move information from a field device across a network to a server hosting application.

It requires a lot of work for a data packet to read, be packaged and shipped across the network(s), unpacked, and written into a database. And it takes time. Traditional hub-and-spoke architectures work very well for large, centralized, slow-to-change systems, but they do not cut it when it comes to speed and performance.

|

|

1. Today's control systems are centralized and hierarchical, with long scan rates, and operating at limited scale. Autonomous utility systems are decentralized, at times peer-to-peer, and often "systems of systems." These are scalable, secure, and more fault-tolerant. Courtesy: Real-Time Innovations |

In performant systems, servers are present but not relied upon. Instead, data and devices become the key focus (Figure 1). IIoT systems are all about performance; mission critical, life-saving, scalable, secure, much more detailed than just turning on or off lights with a smartphone. But in order for these systems (or even systems of systems) to exist, immediate and accurate data must be available in the form needed, in the location(s) needed, and in the security needed. The IIoT has been solving these requirements for years with the concepts of data-centricity and a databus.

Another consideration in the move to distributed systems is ownership and access. For years, utility systems have been focused on what the utility owns. Equipment, network, land–all have been in the close control of the utility. Today, there is an absolute dissolving of this ownership model; DERs come in many shapes and sizes, and ownerships. But just because the utility doesn't own it, does not mean it doesn't contain vital information. IIoT systems allow for utilities (really all players) to have secure, real-time information to pertinent data, with any type of network infrastructure.

Data Centricity

Data centricity is a relatively new concept to the power industry. For years, the world has been able to run (and run well) through device scans and instructions being communicated in terms of seconds or even minutes. In this setting, data centricity is not needed.

However, when the requirements change (think in terms of frequency or voltage support, disparate systems, fast control, etc.), data centricity becomes a requirement. Round trips for data–the kind from the device to a server and back–are simply too time-consuming.

Data centricity "empowers" the data on the device, and then makes it available to any connected device or system via a databus. Through a data framework known as "publish/subscribe" or "pub/sub," devices publish data to a common virtual network connection (that is, the databus) and any number of subscribers can receive the data. In the pub/sub world, there is extremely low latency as long as modern IIoT data connectivity software is employed, such as Data Distribution Service (DDS).

The term "bus" has been with electric utilities since the beginning. The bus establishes a common connection point where everything connected to it has access to the "what" that is there (such as voltage, current, etc.). In an over-simplified description, the station bus and databus look quite similar on paper.

However, rather than energizing connected devices, the databus and the devices that attach to it are "data empowered." Going back to the discussion on data centricity, the databus becomes a main component; just because a device has modern IIoT capabilities doesn't mean much if it cannot connect to and communicate with similarly equipped devices.

|

|

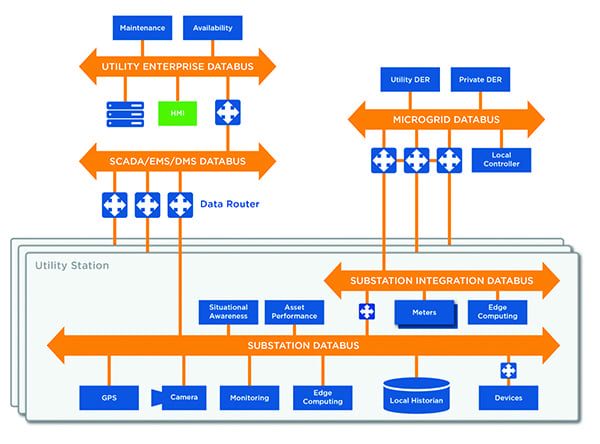

2. This graphic illustrates layered databus deployments. Most IIoT connectivity frameworks will operate on existing network infrastructure, and because of the nature of the data-centric connectivity, use very little bandwidth. Several projects already are operating using this structure. Courtesy: Real-Time Innovations |

Further, the databus concept (Figure 2) allows for layering–keeping pertinent data on one layer available for anything/anyone interested, and then making individual data available to be moved to other databuses. This means a utility no longer needs to move everything to a server to process. Instead, the meaningful data is delivered where needed, when needed, and in the parameters needed (secured, durable, acknowledged, etc.).

Resilience and Security

Today's conversations about the power grid often focus on resilience. Utilities, the military, university campuses, hospitals, municipalities–everyone is looking for ways to increase resiliency.

In IIoT designs, resilience is realized through a decentralized architecture that provides for instant reconfigurability. Subsystem discovery and fault-tolerant failover, for the devices, the software, the subsystems, and the backend computing environment then become requirements. When the data needed to optimize a system does not need to make a roundtrip to a server (that may or may not be available), resiliency increases. When there are no single points of failure, fault-tolerance increases dramatically.

Naturally, resiliency and security go hand-in-hand. Best-practice security is provided with a data-centric security capability, developed for a Department of Defense open architecture that layers on top of standard IIoT network and endpoint security to provide greatly enhanced end-to-end system security. What this means for the power industry is that even legacy devices, modernized quickly and cheaply with IIoT capabilities, can be secured and participating in the databus environment in minutes or hours.

A key takeaway is that most IIoT technology is additive, not replacing. In a market with seriously disruptive times ahead, a "rip-and-replace" offering will go nowhere.

Tying It All Together

As we move into the emboldened DER future, utilities and generation companies must rapidly integrate proven applications into larger systems-of-systems using the power of the IIoT (edge-through-backend connectivity, fault tolerance, cloud analytics, and business intelligence).

Capabilities such as auto-discovery of new installations, provisioning, and authentication, all will need to happen with highly automated processes. Simply put, trucks cannot be rolled each time a new device is available and of interest to a utility.

Some of the core efforts of the Industrial Internet include:

- ■ Security that empowers militaries across the globe.

- ■ System efficiency through distributed edge to backend control.

- ■ Analytics, optimization, and management applications with plug-and-play capabilities.

Most everyone will agree that DERs are not only present, but will have a direct and tangible impact on the future of the grid. While the road ahead is still obscure, the learning and standards deployed through IIoT systems will greatly aid the grid's journey. We in the electric industry are indeed fortunate to have giants' shoulders to stand upon. ■

–Erik Felt is the market development director for Future Grid at Real-Time Innovations (RTI), where he is focused on bringing the benefits of IIoT standards and systems into the utility market. He is scheduled to take part in POWER magazine's Distributed Energy Conference at the Gaylord Rockies Resort, in Denver, Colorado, Oct. 30–Nov. 1.